|

Tools #1

Welders

Authored by Wes Vann, last revised on April 12, 1997

PLEASE NOTE; Any time working with welders wear the correct welding goggles for eye protection. The goggles for gas welding are not the same as those required for arc welding!

Any gas cylinder should be handled with care. Even a scuba tank with compressed air can kill if the valve stem gets broken.

GENERAL TERMS;

Base Material; This refers to the two metal objects that you are going to attach.

Flux; Depending on what is being done, flux is basically an acid that cleans the base material and helps remove impurities.

Soldering; When soldering, a metal (solder) that is a combination of tin and lead is melted into the joint of the two base metals. Solder comes in different percentages of tin and lead. When soldering, the base metal is heated up to the point where it melts the solder. A flux or "tinning acid" is required.

Brazing; This is similar to soldering in that the added material is not the same as the base material. A flux is required.

Welding; When welding, the added material is normally the same type as the base material, with the same melting point. Not all types of welding require flux.

It's said that a good weld looks like a stack of quarters that has fallen over. Here is a scan of one of my welds done with the MIG welder (a fairly good weld). This is on a bumper hitch and the metal is 1/8" thick.

GAS WELDERS;

These are the good old Oxy/Acetylene welders. There are two cylinders required. One is pure oxygen and the other is acetylene. Don't confuse "pure oxygen" with the air that we are breathing. As an example, a scuba tank has compressed air and not "pure" oxygen. The oxygen doesn't by it's self burn, but is required for complete combustion. The acetylene is the fuel that burns.

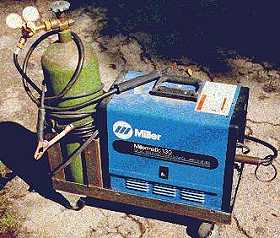

With an oxy/acetylene welder it is possible to braze or weld. It's also possible to get a cutting tip (cutting torch) to make quick cuts. (the photo above shows the cutting torch)

Brazing is where the metal that is to be attached is heated up and a brazing rod is fed in. It's similar to soldering in that the base metal isn't melted, only the brazing rod. A flux has to be added when brazing and it is sometimes a coating on the rod. When done brazing, the flux leaves a glass left-over that has to be removed.

When welding, the base material is melted and the rod is fed into the molten puddle.

When using a cutting torch, once the metal has melted, a lever is pulled and additional oxygen is fed in. This caused the melted area to be both blown out and oxidized.

One of the problems with gas welding is the amount of heat that goes into the material. That is why that it's not reasonable to use it for repairing body panels. When heated excessively, the thin metal warps.

ELECTRICAL WELDERS;

Arc Welders; I normally refer to these as stick welders. There is a grounding cable, from the welder, that is clamped on the object to be welded. The other cable from the welder goes to the handle that grips the welding rod. When welding, the rod is held close to the metal and there is an arc that flows from the tip of the rod to the metal. The material of the rod is transferred to the base metal and the weld is built up.

Wire Welders & Mig Welders;

These work great for body panel replacement. A wire welder has a spool of wire within the welders cabinet. This wire runs through the cable and out the welders tip. When welding, the wire is fed at a speed that should match how fast it is deposited on the base material. A "Mig" welder is a wire welder with a gas feed at the welding tip. The gas forms an area of gas where the welding occurs. As a result, the welding isn't exposed to "air" while welding. There are various gas mixtures used (I have had good luck with argon/co2).

TIG and HeliArc Welders; This set-up uses a tungsten tip at the welding arc. There is also a gas feed to create the atmosphere that the welding occurs in. In Heliarc welding, the gas is helium. The tungsten tip is slowly consumed and a rod has to be added as you go.