|

Tools #3

Electrical Connections

Authored by Wes Vann, last revised on May 16, 1997

GENERAL TERMS;

Lug connectors; These are the connectors that are held in place with a screw. Most are full circle and require that you remove the screw to add a wire, some are just part circle and can be added by just loosening the screw.

Butt Splice; This is where two wires are connected together. The photo shows a soldered crimp connector. The upper wire has had the heat shrink tubing put in place and shrunken using a heat gun.

"3M Scotch-Lok" connectors; These little guys are a great invention. There are various types and options, but the idea is the same. They enable you to splice a wire into an existing wire without cutting it. How they work is that there is a metal piece that cuts through the wire insulation. What you do is insert the wires (they have to be the correct size for the connector used), use a set of pliers to depress the metal piece in, they fold over the plastic cover.

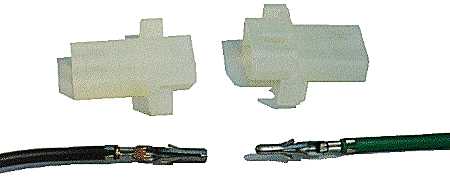

"Molex" connectors; Just like Kleenex, this is both a company name and generic name for a type of connector. The connector pins are round pins. There are various pin counts possible and the nylon block is keyed so that it can't be connected wrong.

Weather-pac connectors; These have a rubber boot to seal out moisture. They are used on fuel injection wiring. (I can't find a photo)

"Mil-spec" connectors; Military Specification. These are the most positive connector that you will find! They are also the most costly!

Crimp connectors; These are the type connectors that you buy at your auto parts store. They could be spade, lug, or butt connectors. Normally there is a plastic cover on the part that is crimped. There are three different colors and the colors are for different size wire. Red is the smallest, blue is the standard size, and yellow is the largest.

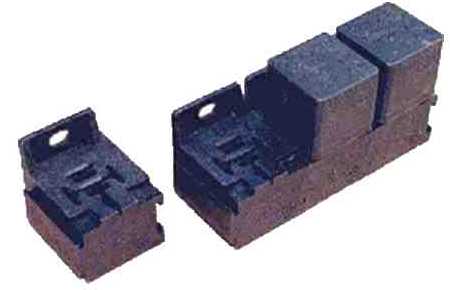

Relays; The most common relay that is added to a car for things like fog lamps and such is the 30 amp BOSCH. This little guy is great and VERY usefull. The one problem is that most places that sell them don't know that there is a connector with a mounting tab right on it. This makes it easy to replace a questionable relay. There is a slot on the side that enables you to mount several together! When you get the relay, make sure that it's one of the ones with 5 connectors. The 5 connector relays have both a "normally open" and a "normally closed" input.

Solder; When soldering, a metal (solder) that is a combination of tin and lead is melted into the joint of the two base metals. Solder comes in different percentages of tin and lead. Rosen core solder is a solder where there is a flux core inside the solder.

Flux; This is a mild acid used to clean off any corrosion. It comes as a paste that is put on the wire prior to soldering. It is also possible to get "rosen core" solder that has the flux in it. I have the best luck with the paste type flux.

Tinning acid; This is a fairly strong acid that is used if there is a fair amount of corrosion on the item to be soldered. Tinning acid is used when soldering the copper pipes in your house.

Soldering Iron; A soldering iron stays hot as long as it's plugged in. Used for soldering wimpy things..

Soldering Gun; Used for soldering and is only hot while the trigger is pulled and held in. Most have two heat ranges that are controlled by how far you pull in the trigger. The tip on the soldering gun in the photo is reversed from the standard. I just like it that way.

Heat shrink tubing; This stuff is great. As you could guess,

when heated, it shrinks to about 75 percent of it's diameter. The pro way

to shrink it is to use a heat gun (much like a hair dryer), however, it's

also possible to use a lighter or match.

Comments and Ideas;

How to do a good solder connection:

The metal of the wire and the terminal has to be clean and free of corrosion. This is the reason that flux is used. Normal flux for soldering is a mild acid. If needed, try tinning acid.

Put a light coat of the flux paste on the connection.

Heat the connection with the soldering gun until the connection is hot enough to melt the solder. The idea here is that the connection melts the solder and not the tip of the gun!

The solder will flow into any area where the metal is hot enough to melt the solder. A good job will have a smooth shiny solder surface.

Any excess flux should be wiped off.

Heat shrink tubing:

When using heat shrink tubing, you have to have several sizes. The tubing has to be slid on the wire prior to attaching the terminal due to the fact that normally the correct size tubing will not fit over the terminal afterward.

While soldering the connection, you have to be careful that the tubing doesn't get heated.

After the connection has cooled off, slide the tubing into place and heat it up with a heat gun or lighter.

Molex connector crimpers;

A special crimper is required for molex connectors. The crimper isn't all that costly, but it's special. There is also a special tool for removing the pins out of a Molex connector. Once again, it's not really costly, it's just special and you will need it.

If you look at the photo of a molex connector, you will notice that each connector has two crimps on it. One crimp is on the exposed wire and the other is on the insulation.

Mil-spec connectors;

You have to solder the wires into these connectors. The connectors can be gotten in all sorts of configurations of connector count and wire size. It is possible to purchase used connectors and reuse them (really saves money thanks to our government).

The connectors have a barrel that rotates to hold the two sides together. It's kind of like a camera lens.

Are they worth it? Look at any Indy race car for what type connectors they use.